Simple Program Cnc Turning

THE AUTHOR PROVIDES THIS SOFTWARE 'AS IS' AND ANY EXPRESSED OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

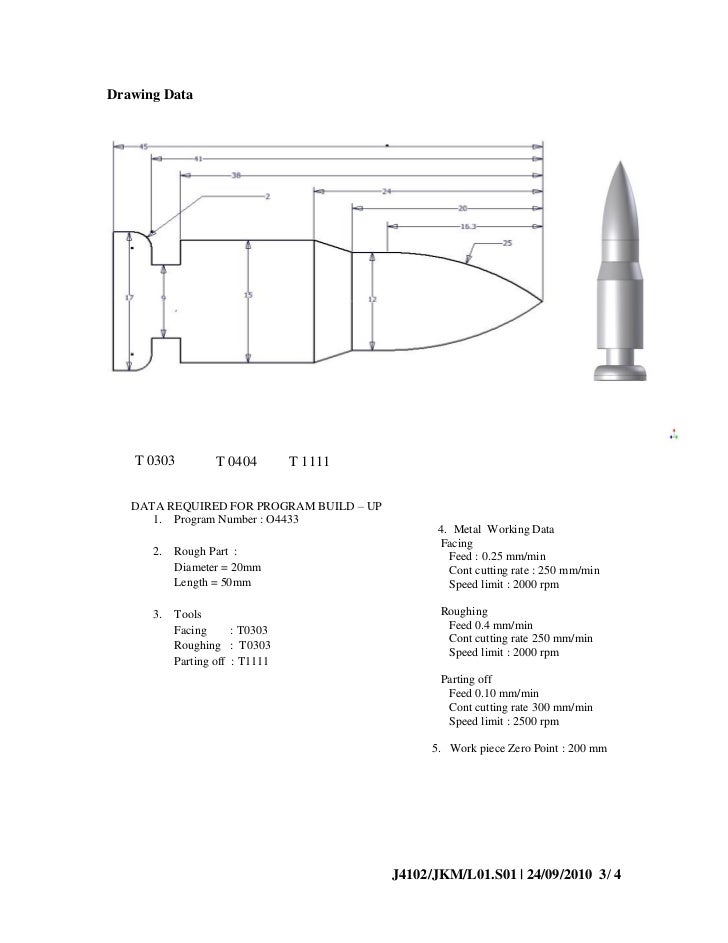

CAMWorks 2 and 4 Axis Turning software for programming CNC lathe machines includes automatic roughing. Program CNC lathe machines including automatic roughing.

CNC Lathe Programming for Turning CNC Lathe Axes CNC Lathes come in a variety of configurations, but for the basics, we’ll stick to the simplest and most common setup–2 axes. Simple CNC Lathes use a Z-axis, which is parallel to the spindle axis, and an X-axis, which is at right angles to the spindle. In, the display looks like this: X-Axis runs top to bottom while Z-axis runs left and right The G-Wizard E ditor will automatically switch its axis display when you change the machine type from mill to lathe and vice versa. The next step up from a 2-axis lathe would be a 3-axis lathe. Rather than add the Y-axis, a 3-axis lathe typically has X, Z, and C axes. C is a rotary axis parallel to the spindle axis and Z. In essence, it allows you to clock the spindle to specific angles.

A three axis lathe with live toolign can do fairly arbitrary milling jobs on the part in the lathe chuck. Black Mesa Source (no-steam Standalone). We won’t spend any more time talking about C-axis programming in this section because it’s beyond the scope of a simple introduction to CNC turning. Diameter Versus Radius Mode Your CNC lathe’s controller will be setup to start in either diameter or radius mode. In diameter mode, X-axis values specify diameters, while in radius mode, they specify a radius from the axis. As you would expect, diameter mode X-axis values are exactly twice what the radius mode values are, so it is important that you know which mode your lathe is using.

Learn to read and write G-code programs for 2-axis computer numerical controlled lathes. For various turning. A simple programming exercise that will. Learn Fanuc CNC lathe programming from the examples on this website. The G71 turning-boring cycle: This is a simple example.

G-Wizard Editor has a revision command that lets you change programs back and forth between diameter and radius mode: Lathe diameter mode is simple: multiply all the X’s by 2 As you can see, it ain’t rocket science–we use the Adjust Addresses Revision to multiply all the X’s by 2. Some machines may also have the ability to change between radius and diameter mode using special g-codes.. Many machines also implement a gcode that lets you switch back and forth: – G190: Radius mode. – G191: Diameter mode. Basic G01 and G02/03 Moves: Lines and Arcs The CNC Lathe can make the same basic moves as the mill–G01 for lines and G02/03 for arcs (plus G00 for rapid motion in a straight line).